In this article, we’re talking about yield strength — one of the many measurements and specifications a fastener needs to meet to qualify for a particular grade or property class.

We’ll talk about what yield strength means, how it’s measured, and how it relates to some other common fastener terminology.

What Is Yield Strength?

Yield strength is the load that’s carried at the point where a fastener permanently deforms. It’s one of the measurements set by a particular standard (ISO, ASTM, etc.) that a fastener must meet to qualify for a certain grade or property class.

Here’s a better explanation, perhaps:

When subjected to enough force, steel will begin to stretch. If the amount of force is low enough, the steel will elastically return to its original shape when the force is removed. But if the force becomes strong enough, the steel will stretch and not return to its original shape. This amount of force is the yield strength.

If you’d like an example, here are some of the most common ASTM A354 fastener grades and what the specification requires their yield strength to be:

| ASTM A354 Grade | Yield Strength |

| Grade BC (nominal diameter ¼ – 2 ½”)

Grade BC (nominal diameter 2 ⅝ – 4”) |

109,000 psi

94,000 psi |

| Grade BD (nominal diameter ¼ – 2 ½”)

Grade BC (nominal diameter 2 ⅝ – 4”) |

130,000 psi

115,000 psi |

Keep in mind that these are just some examples and specifications. Yield strength always changes between fastener size and grade (or property class).

How to Calculate the Yield Strength of a Fastener

Compared to some other fastener specs like proof load and tensile strength (more on those later in this article), yield strength is the one that’s tested the least. When yield strength is called for, it’s often in place of the proof load test. It just depends on the spec. For example, ASTM F606 states that testing yield strength is an alternate option for meeting the proof load requirement.

Although it’s not as common as some others, yield strength still an important test to understand if your spec does require it. We’ll describe the procedure below.

RELATED: Need a specialty bolt, screw, or stud? Wilson-Garner can help.

Yield Strength Testing Procedure

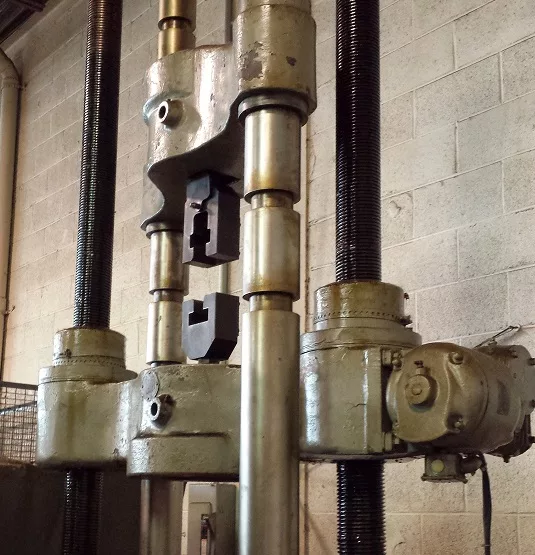

A fastener’s yield strength is determined using a tensile machine, which looks like this:

Here’s a general overview on how it works.

The fastener is placed in the middle slot of a tensile machine, then the load is applied for a specified amount of time (usually seconds).

ASTM F606 allows for multiple methods of determining yield strength, but the most common used is the “offset method.” The offset method involves measuring fastener elongation and plotting the results on a stress-strain diagram. The stress is determined at an offset, most commonly at 0.2% of the length of the fastener. Wherever the curve deviates on the stress-strain diagram is equivalent to the yield strength of the fastener.

When looking at yield strength values calculated using the offset method, you’ll see the percentage offset in parenthesis after the term “yield strength,” similar to this:

- Yield strength (0.2% offset) = 57,000 psi

Why Is Yield Strength Testing Important?

Yield strength testing is important because it helps us know how much force can be applied to a fastener before there is risk of deformation. The test verifies that the fastener meets the minimum requirements to qualify for a particular grade or property class.

From there, this information can help us understand if the fastener is safe enough, strong enough, and well-suited for a particular application.

Yield Strength vs. Tensile Strength vs. Proof Load

Yield strength is related to tensile strength and proof load, but there are key differences between them. An understanding of these terms, how they relate to one another, and how they differ from one another is important for safe and effective fastener production.

Here’s a look at each of their definitions, so you can see the differences for yourself:

- Yield strength: the load that’s carried at the point where a fastener permanently deforms.

- Proof load: the minimum amount of force that a fastener must be able to withstand for a given amount of time without permanently deforming.

- Tensile strength: the maximum amount of force a fastener can withstand before fracturing.

So there are really three levels of force we’re discussing here, and yield strength falls somewhere in the middle. If you’d like a better idea of how yield strength, tensile strength, and proof load compare and contrast with each other, check out this blog.

And if you’re still a little lost on these terms, or possibly some other technical fastener terminology, don’t hesitate to head to our glossary.

Contact Us for Custom Fasteners Manufactured to Any Specification

If you need per-spec fasteners, we can help. At Wilson-Garner, we’re your top source for limited-run, custom bolts, screws, and studs. Our testing and production processes ensure you get the exact fasteners you need, the first time.

To learn more or request a quote, contact us online.