The fastener industry is filled with so many technical terms and measurements that it can be difficult to keep them all straight. In this article, we’re breaking down one of them for you: proof load.

We’ll talk about what proof load is, how it’s tested and measured, and how it relates to some other common industry terms.

What Is Proof Load?

Proof load is the minimum amount of force that a fastener must be able to withstand for a given amount of time without permanently deforming. It’s a measurement that’s set by a particular standard (think ISO, ASTM, etc.), and fasteners must meet it to qualify for a specific grade or property class.

Let’s take the SAE J429 standard for example. Here are some of the most common SAE J429 fastener grades and what the standard requires their proof load be:

td {padding: 10px;border: 1px solid black;border-collapse: collapse;}

| SAE J429 Grade | Proof Load |

| Grade 2 (nominal diameter ¼ – ¾”)

Grade 2 (nominal diameter ¾ – 1 ½”) |

57,000 psi

36,000 psi |

| Grade 5 (nominal diameter ¼ – 1”)

Grade 5 (nominal diameter 1 – 1 ½”) |

92,000 psi

81,000 psi |

| Grade 8 (nominal diameter ¼ – 1 ½”) | 130,000 psi |

Of course, these are just a few examples and measurements. Proof load always changes between grade (or property class) and fastener size.

How Do You Determine the Proof Load of Fasteners?

In order to determine proof load, fasteners undergo a proof load testing procedure. Below is an overview of how that procedure works and why it’s important.

Proof Load Testing Procedure

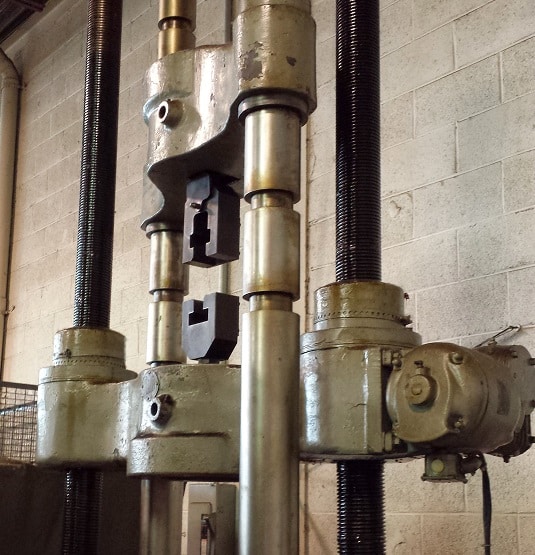

To test proof load force, a tensile machine is used. Here’s a photo of one:

The length of the fastener is measured before it’s inserted in the middle slot of the machine. The machine then exerts a vertical force onto the fastener and measures that force as the fastener holds or deforms. The test is completed for a specific amount of time (usually seconds), which is dictated by the standard. Finally, the length of the fastener is measured again to ensure the part wasn’t permanently deformed during the test.

For example, if we were checking a ⅜” diameter part made to meet SAE J429 Grade 5, we’d check the standard and see that for parts ¼-1” in diameter, the proof load requirement is 92,000 psi for 10 seconds. Then we’d run the proof load test per the specifications required. If the fastener can pass the test without permanently deforming, it has passed proof load.

Why Is Proof Load Testing Important?

Proof load testing is an important practice that helps us be certain that a fastener can withstand a minimum force for a given amount of time without deforming. Fasteners are manufactured for a certain grade, then we run tests to verify that it meets those minimum requirements.

In turn, this information helps us understand if the fastener is safe and strong enough to use for its intended purpose.

RELATED: Need a specialty bolt, screw, or stud? Wilson-Garner can help.

Proof Load vs. Yield Strength vs. Tensile Strength

After learning about proof load, you may be wondering how it relates to similar terms you’ve heard: yield strength and tensile strength.

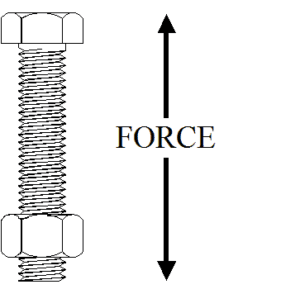

Proof load, tensile strength, and yield strength are all measurements set by a standard that fasteners must meet in order to qualify for a certain grade or property class. The terms are related to the load that a threaded fastener can hold when pulled perpendicularly from its head, as you can see in the figure below.

However, there are some key differences between these terms and what they mean for fastener testing and production. Here are their definitions so you can analyze them:

- Proof load: the minimum amount of force that a fastener must be able to withstand for a given amount of time without permanently deforming.

- Yield strength: the load that’s carried at the point where a fastener permanently deforms.

- Tensile strength: the maximum amount of force a fastener can withstand before fracturing.

Basically, there are three levels of force we’re talking about here. Proof load is the lowest level, yield strength is a bit higher, and tensile strength is the highest level. For more information and examples on how these measurements compare and contrast, head over to this blog.

And for a deeper understanding of some technical fastener language, check out this glossary of terms.

Trust Wilson-Garner to Manufacture Custom Fasteners According to Your Specifications

At Wilson-Garner, we specialize in custom, limited-run fasteners for a range of industrial applications. You give us your blueprint, and we’ll take it from there — no matter what standard or grade you need to comply with.

Give our team a call or contact us online to learn more about how we can help you.

Comments are closed.