Where precision meets performance.

Our custom fastener manufacturing process is designed to ensure you get the exact fastener you need, the first time around.

Stages of Fastener Manufacturing

Different specifications call for different manufacturing solutions. Consequently, the fastener manufacturing process varies from part to part. Below is a general example.

Raw Material Selection

The right material will vary based on your application. At Wilson-Garner, we specialize in parts made from alloy steel and carbon steel, both known for being relatively inexpensive with high levels of tensile strength, durability, and ductility.

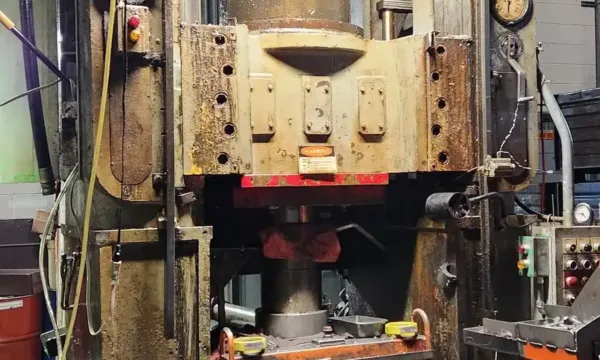

Cold Forming vs. Hot Forging. Vs. Machining

There are three common ways to manufacture steel fasteners: cold forming, hot forging, and machining. We most commonly use a cold forming process due to its strength-bolstering benefits, but we’ll also employ machining when it makes sense to do so.

Heading

Utilizing cold-forming techniques, our first step is to form the fastener head. We take the raw material and extrude, upset, and head it. This is typically done in one to five or more hits depending on the shape of the head and the amount of material being moved.

Trimming

Not every part needs to be trimmed, but for those that do, we follow this process. Once this is finished, the fastener’s head is fully formed and functional.

Rolling

While some manufacturers cut threads, we’ve found rolling to yield more accurate, durable, and resource-efficient results. We sometimes use a Reed roller to roll threads one at a time — a highly intensive process. Other times we use a flat-die roller to roll them. It just depends on the specifications of the part.

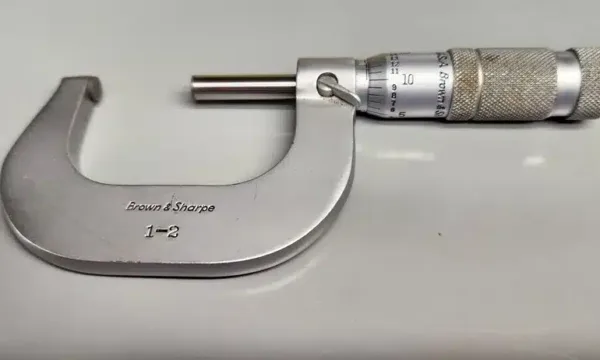

QA Part 1

Our team completes a dimensional inspection to ensure all dimensions are within tolerance.

Coating & Plating

We partner with other trusted manufacturers to handle heat treatment, coating, and plating as needed.

Re-Roll & QA Part 2

When necessary, our team re-rolls the threads to remove any nicks or burrs that may have been added in heat treatment or plating processes and make sure threads gauge properly. Then, we complete one final inspection before the parts are ready to ship.

Why Wilson-Garner?

Per-spec

The exact fasteners you need, every time. Submit an RFQ and blueprint, and we’ll run the job.

Limited-run

Small batches of the parts you need, as you need them. No bulk ordering required.

American-made

Manufactured at our plant in Harrison Township, Michigan for 50+ years.

Helpful Resources

Have questions about custom fasteners, the manufacturing process, or industry-specific solutions? Get answers.

One method of manufacturing steel fasteners stands out for its efficiency, precision, and cost-effectiveness:...

February 2, 2022Rolled Threads vs. Cut Threads

Generally speaking, there are two main methods of producing external threads on a fastener:...

October 13, 2021What Is Cold Forming?

As you may know, there are several ways to make fasteners, including cold forming,...