Understanding the mechanical properties of bolts is crucial for ensuring the safety and integrity of any structure or machinery they’re used in. Shear strength is one of those properties, and that’s what this article is all about. We’ll cover:

- What shear strength is

- How shear strength is different from tensile strength

- Shear bolts and their characteristics

- How to calculate bolt shear strength

What Is Shear Strength?

Broadly speaking, shear strength is the maximum stress a material can withstand before it fails in shear. It’s a measurement used in a number of engineering applications.

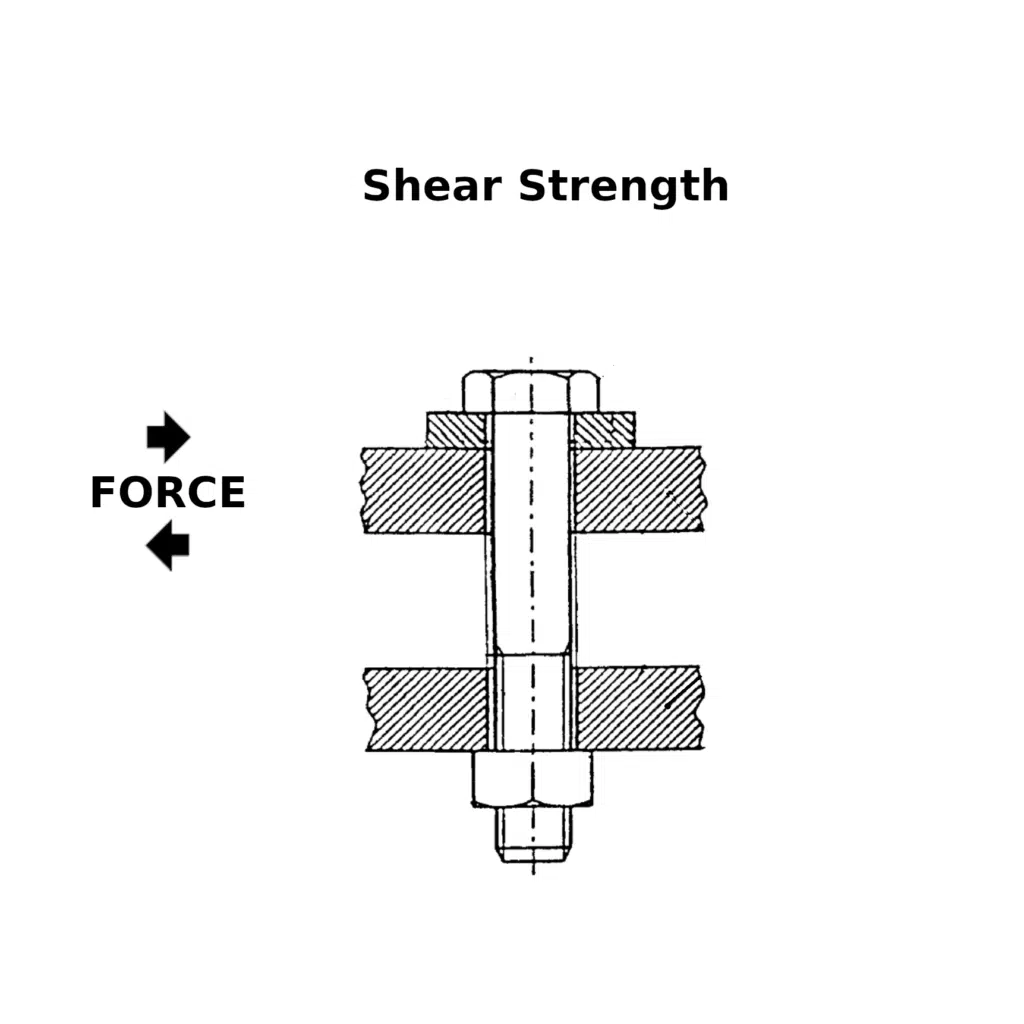

When you apply that definition to bolts, shear strength is a measure of a bolt’s ability to resist forces that attempt to slide it apart.

This is a critical component in applications where bolts are subjected to loads that don’t act along the axis of the bolt but rather across it, like in joints that experience lateral forces (sliding away from each other in opposite directions).

Failure in shear can have destructive results — think structures collapsing, heavy machinery malfunctioning — so it’s important that engineers carefully consider the shear strength of bolts in their designs.

Shear Strength vs. Tensile Strength

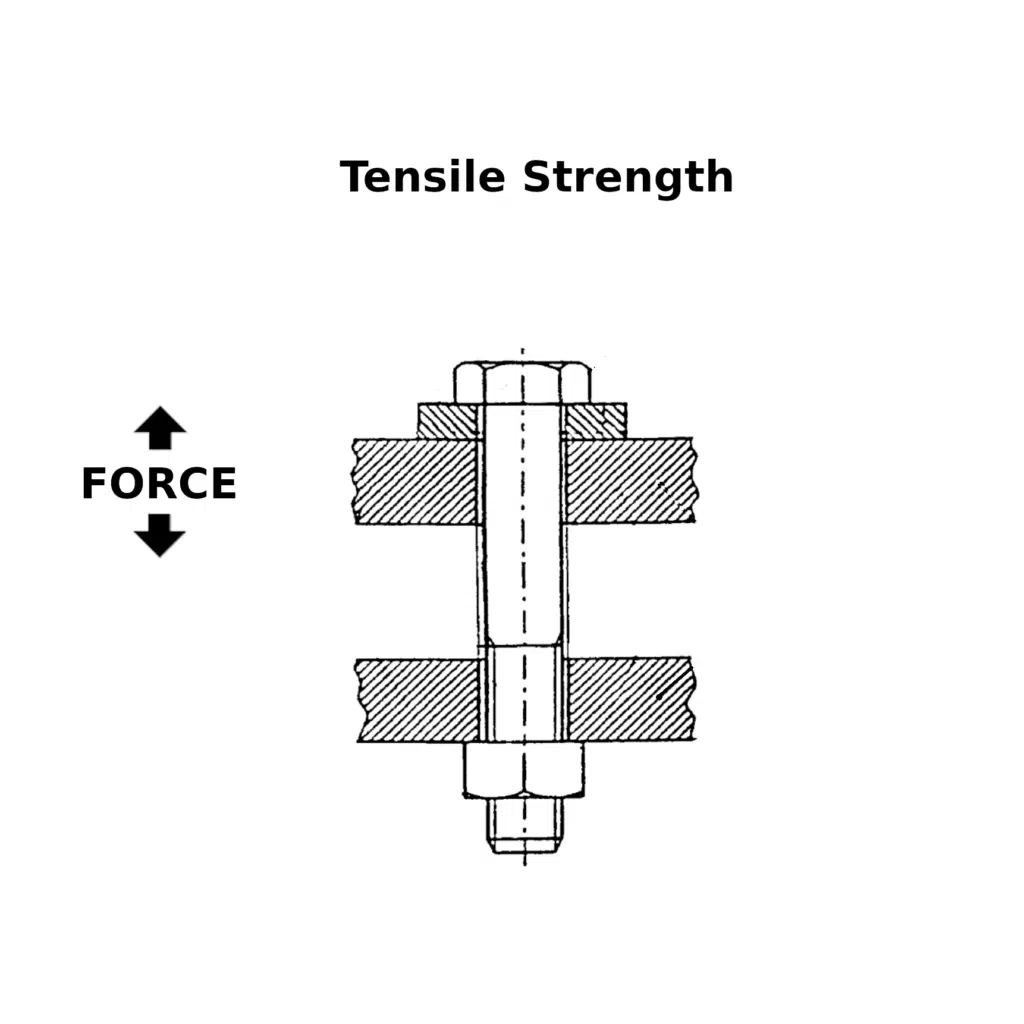

Shear strength and tensile strength are both essential measures of how well a bolt can withstand force without breaking. The difference between them is that shear strength measures a bolt’s resistance to sliding forces, and tensile strength refers to its ability to withstand pulling forces along its length, or axis.

Tensile strength is often higher than shear strength for the same bolt, as all materials are generally stronger in tension than in shear. Think about it: a bolt subjected to a large tensile load will elongate until it eventually snaps. A bolt under a large shear load will fail, or snap, along its cross-sectional area. There’s simply less wiggle room.

In practice, it’s important to know the difference between these two strengths and choose the right one to focus on for your application. In structural joints where shear forces dominate, choosing a bolt with high shear strength is more critical than selecting one with high tensile strength.

What Is a Shear Bolt?

A shear bolt is a specialized fastener designed specifically to fail in shear at a predetermined force. This type of bolt is commonly used in applications where controlled failure is necessary to protect more critical components of a system. It will help to avoid more significant damage and costly repairs, as it can be easily replaced after a failure.

Some key characteristics are:

- Precise shear point: The bolt is designed to shear, or break, at a specific load to prevent damage to more expensive or vital components.

- Low-tensile material: The bolt is likely made from materials with low tensile strength to ensure they fail at the desired shear load.

- Application-specific design: The bolt is tailored to specific applications where predictable shear failure is a safety feature.

You’ll often find shear bolts in agricultural machinery, snow blowers, and certain types of industrial equipment.

Examples of High Shear Strength Bolts

Standard bolts can have a good amount of shear strength. However, for applications requiring exceptionally high shear strength, you’ll want to choose any of these high shear strength bolts:

- Grade 8 bolts: Known for their high shear strength and tensile strength, Grade 8 bolts are commonly used in heavy machinery, automotive applications, and structural connections. They’re made from carbon alloy steel, quenched, and tempered for added strength.

- A490 bolts: A490 bolts (from ASTM A490) are used in structural connections — most often construction applications — and are known for their high shear strength.

- Inconel bolts: Inconel is a nickel-chromium-based superalloy. Bolts made from Inconel have extreme shear strength, particularly in high-temperature environments. Therefore, they’re most often used in aerospace and high-performance automotive applications.

- Stainless steel bolts: While not the strongest in tensile strength, certain grades of stainless steel bolts offer excellent shear strength and are used in marine, aerospace, and chemical processing industries.

How to Calculate Shear Strength

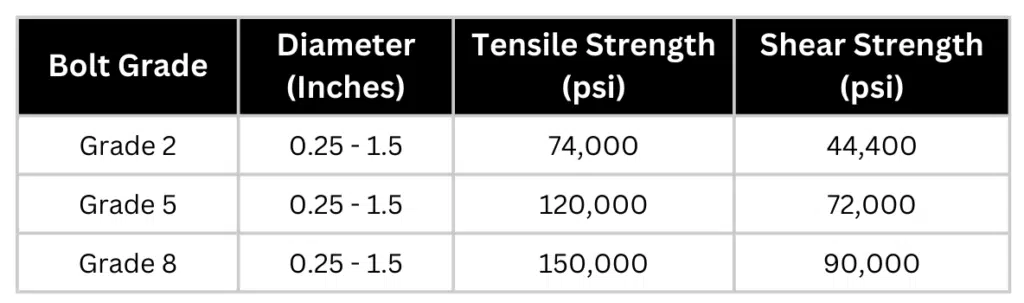

Surprisingly, there are no shear strength values or requirements in ASTM specifications like there are for other strength measurements (e.g. tensile strength). Instead, the Industrial Fastener Institute articulates shear strength as about 60% of the minimum tensile strength.

So, if a Grade 8 bolt has a minimum tensile strength of 150,000 psi, the shear strength would be 90,000 psi.

Bolt Shear Strength Chart

Here are some more shear strength values, plus their respective tensile strength equivalents, for common bolt grades.

Please note that these values are general guidelines and may vary based on specific material properties and manufacturing processes. You should always cross-check with manufacturer specifications or precise measurements.

Looking for High-strength Bolts?

Whether you’re working with high shear strength bolts or calculating shear strength for a specific application, hopefully this article gave you some practical insights. If you have further questions or are interested in ordering high-strength fasteners, get in touch. We’re happy to make you a quote or steer you in the right direction.