For any fastener to qualify for a certain grade or property class, it needs to meet a particular set of physical criteria and specifications. One of the most common and important specifications is tensile strength.

Below we’ll take a look at what tensile strength is, how it’s tested, and how it relates to other common fastener specs.

What Is Tensile Strength?

A fastener’s tensile strength is the maximum amount of force a fastener can withstand before fracturing. It’s also referred to as ultimate tensile strength, or UTS. It can be affected by factors like material composition, hardness, and size of the part.

Tensile strength is one of the measurements set by a quality standard — like ISO, ASTM, SAE etc. — that fasteners must meet to qualify for a grade or property class. Each standard has its own tensile strength requirements.

Let’s use ISO 898-1, for example. The chart below shows three different ISO 898-1 property classes for bolts and what tensile strength they require.

| ISO 898-1 Property Class | Min. Tensile Strength

(≤ 16mm diameter) |

Min. Tensile Strength

(> 16mm diameter) |

| Class 8.8 | 800 MPa | 830 MPa |

| Class 10.9 | 1,040 MPa for all sizes | |

| Class 12.9 | 1,220 MPa for all sizes | |

How Do You Determine the Tensile Strength of Fasteners?

To determine the tensile strength of a fastener, the fastener must undergo a testing procedure called a wedge tensile test. Below is an overview of how that test works and why it’s important.

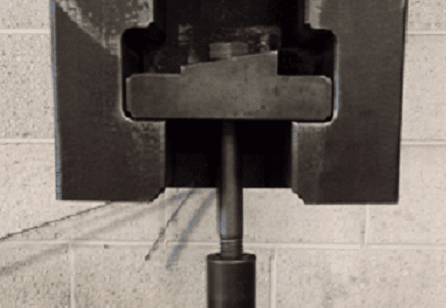

Wedge Tensile Test

During wedge tensile testing, a wedge is placed under the head of a fastener, then force is applied until the fastener breaks. The wedge is used because it puts extra stress on the junction of the head and the body of the fastener. This ensures the integrity of the junction.

If the fastener breaks at a force greater than the minimum tensile requirement in the spec, the fastener has passed the tensile test. However, the break must not occur at the junction of the head and the body of the fastener. If the break does occur there, the fastener has failed the tensile test regardless of the force at which the break occurred.

Why Is Tensile Strength Testing Important?

Tensile strength testing is important because it shows us how much force can be applied to a fastener before it will break. You can probably guess why this is an important piece of information to know. It helps solidify that the fastener is strong enough and safe enough to be used in specific conditions and for a specific purpose.

If you get fasteners that don’t have a high enough tensile strength for your application, you’ll have to deal with fastener breakage and failure issues. On the flipside, if your fasteners’ tensile strength is higher than necessary, you’ve probably wasted money on that added strength.

Tensile Strength vs. Proof Load vs. Yield Strength

Now, you may wonder how tensile strength relates to other industry terms like proof load and yield strength.

Tensile strength, proof load, and yield strength are all measurements set by a standard that fasteners need to meet to qualify for a particular grade or property class. They’re all related to the load a threaded fastener can bear when pulled perpendicularly from its head. The diagram below shows an example of this.

However, there are key differences between these terms and how they relate to fastener testing, production, and performance. Here’s a side-by-side look at their definitions.

- Tensile strength: the maximum amount of force a fastener can withstand before fracturing.

- Proof load: the minimum amount of force that a fastener must be able to withstand for a given amount of time without permanently deforming.

- Yield strength: the load that’s carried at the point where a fastener permanently deforms.

To summarize, there are different levels of force measured here. Tensile strength is the highest level, followed by yield strength, then proof load. For a closer look at how these terms compare and contrast, read this blog.

If you weren’t aware of any of these terms, and maybe a few other ones, too, this glossary-style blog is full of helpful fastener terminology.

RELATED: Need a specialty bolt, screw, or stud? Wilson-Garner can help.

Get Quality Fasteners Manufactured to Your Specifications

At Wilson-Garner, per-spec and limited-run fasteners are our specialty. You hand us the blueprints and we’ll deliver the parts you need, in the quantity you need, and with the level of quality you need.

Give us a call at (800) 656-2658 or contact us online to learn more about our services.