Bolts are an essential component in the manufacturing and engineering industries. From the intricate machinery of automobiles to the robust structures of bridges and buildings, bolts play a vital role in keeping everything together. For this reason, it’s important to understand what bolts truly are, plus all the types, grades, nomenclature, and functionalities associated with them.

We cover all of this information below. Feel free to use the table of contents below to jump to a specific section that interests you.

- Definition of a Bolt

- The Difference Between a Bolt and a Screw

- How Is a Bolt Made?

- Common Types of Bolts

- Understanding Bolt Grades

- Bolt Nomenclature for Inch and Metric Parts

Definition of a Bolt

A bolt is an externally threaded fastener designed for insertion through holes in assembled parts. Most often, it’s intended to be tightened or released by torquing a nut.

Want more fastener definitions? Check out this glossary of related terms.

While there are many types of bolts and their designs vary, most bolts have the same general features. They have a threaded cylindrical rod, along with a head at one end and, usually, a nut at the other. Bolt heads are normally larger than their bodies, which is a design that helps distribute the load of the object being fastened over a larger area. The associated nut is used to secure the joined objects in place.

Bolts are used for many applications, with construction, manufacturing, and automotive industries being the most common.

The Difference Between a Bolt and a Screw

Bolts are very closely related to screws. So, how can you tell the difference?

Well, it depends on who you ask. Industry experts have various opinions on the differentiating features of these parts. While we can’t give you a clear-cut answer, we can offer just one opinion from an agency we trust. According to the US Customs and Border Protection (CBP) Agency, these are the definitions for bolts and screws:

- A bolt is an externally threaded fastener designed for insertion through the holes in assembled parts and is normally intended to be tightened or released by torquing a nut.

- A screw is an externally threaded fastener capable of being inserted into holes in assembled parts, mating with a preformed internal thread or forming its own thread, and being tightened or released by torquing the head.

Again, these are definitions from just one of many credible sources. Plus, you can see that the differences are very slight. The CBP also lists 13 other primary and supplementary criteria, which you can explore in this blog.

How Is a Bolt Made?

There are three overarching ways to manufacture bolts: cold forming, hot forging, and machining.

- Cold forming is the process of forming a bolt without heating up the material. It’s accomplished by striking or pressing the material in a die to create desired dimensions.

- Hot forging is the process of heating up material to a point where it becomes malleable, then forming it in a die.

- Machining is the process of using machinery to cut away material until it fits desired dimensions.

Each of these bolt manufacturing processes has its own pros and cons, which you can read about in this article. We use cold forming most often at Wilson-Garner, as we believe it to result in the strongest and highest quality products. However, we also use machining when it makes sense to do so.

If you want an inside look at how we manufacture bolts at Wilson-Garner, check out our bolt manufacturing guide with photos.

Common Types of Bolts

There are many types of bolts, all with different features and use cases. Below is a list of the most common types.

- Place bolts feature self-locking, free-spinning hex heads that prevent loosening due to vibration. Read more about them here.

- Carriage bolts feature reduced body diameters and enlarged, domed heads.

- Hex bolts feature six-sided hex caps on one end. Read more about them here.

- Flange bolts feature washers on the underside of their heads, which help distribute the force from bearing loads more efficiently.

- Shoulder bolts feature a smooth, cylindrical shoulder between their heads and threaded sections. The shoulder is usually larger in diameter than the threaded portion, serving as a guide for the rotation of a mating part.

- Machine bolts feature a square head on one end and a semi-cone point on the other.

- Custom bolts, also known as special bolts, are specifically designed and manufactured for a particular use. Check out our custom bolt manufacturing capabilities here.

Understanding Bolt Grades

Bolt grades are defined by their specific material, plus the strength of that material. They verify the amount of stress a particular bolt can withstand. In general, the higher the number or letter grade, the more stress the part can handle.

There are many governing bodies that create standards for bolt grading systems. SAE, ISO (metric), and ASTM are three examples we often use.

- SAE stands for the Society of Automotive Engineers. SAE grades are some of the most frequently used for inch parts. One important SAE standard is SAE J429, which has bolt grades 2, 5, and 8.

- ISO stands for the International Standards Organization. ISO standards are also referred to as metric standards, and their “grades” are called property classes. Common ISO property classes for bolts are ISO 898-1 Property Classes 8.8, 10.9, and 12.9.

- ASTM stands for the American Society for Testing and Materials. ASTM has several popular standards for bolts (plus other fasteners), such as ASTM A307, ASTM A193, and ASTM A354.

Understanding bolt grades is essential when you’re deciding which part you need for a specific application. For example, you don’t want to use an SAE J429 Grade 2 bolt interchangeably with an ISO 898-1 Property Class 12.9 bolt, as they have very different strength capabilities.

Read more about the different bolt grades and their applications here.

Bolt Nomenclature for Inch and Metric Parts

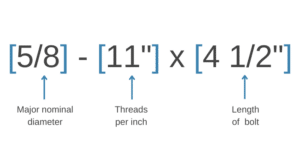

Even seasoned industry experts can need help with fastener terminology. If you’ve run across something like 5/8-11” X 4-1/2” or M8 X 1.25 X 65MM, you might have had no idea what that meant or what to do with the information. We’ll break it down for you below.

Inch Terminology

For inch parts, you might see something like 5/8-11” X 4-1/2”.

In this example, the 5/8 refers to the nominal major diameter of the threads. This is the diameter of the threads as measured at the crests. The 11” refers to the number of complete threads in one inch of the threaded part of the bolt. The 4 ½” refers to the length of the bolt (as measured from under the head, or the widest part of the head).

For a more in-depth explanation of this and how it relates to external threads, you can check out this blog.

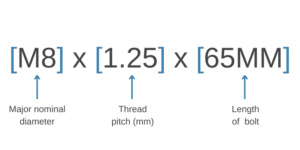

Metric Terminology

For metric parts, you might see something like M8 X 1.25 X 65MM.

In this example, the M8 means that the major nominal diameter of the threads is eight millimeters. The 1.25 refers to the thread pitch, or the distance from one point on a thread to the same point on the next thread. This means the thread pitch is 1.25 millimeters. The 65MM refers to the length of the part (again, as measured from under the head).

For a more in-depth explanation of this and how it relates to external threads, you can check out this blog.

Looking for a Custom Bolt Manufacturer? Contact or Request a Quote Today

Get the custom bolts and other fasteners you need at Wilson-Garner. We specialize in the manufacture of per-spec fasteners in limited-run quantities, ensuring top quality with each order delivered. Give us a call, contact us online, or request a quote today to see what we can do for you.