If you poke around a few industrial websites, you’ll begin to notice plenty of references to ISO 9001 certification. If you happen to be an automotive supplier, you may notice a company reference to being “IATF 16949 certified.” Or, if the company website you’re perusing has an internal lab, you might see a mention of ISO 17205 conformance.

So what do all these acronyms stand for, and why do all these certifications matter? Below, we’ll discuss the difference between IATF 16949 vs. ISO 9001, as well as their importance in industrial manufacturing. We’ll also mention ISO 17205, since that’s one that pops up fairly often as well.

IATF 16949 vs. ISO 9001: What’s the Difference?

IATF 16949 and ISO 9001 are different, but they’re not mutually exclusive. They sit on top of each other sometimes. Think of it as them having the same structure, but ISO 9001 acts as sort of a foundation.

They were both created by different organizations for different, yet similar purposes. So here are the details on what sets them apart.

ISO 9001:2015 — An Overview

Let’s start with ISO 9001, as it’s the most popular and widespread certification across industries. ISO stands for The International Organization for Standardization. This is, as its name implies, an international organization that creates and publishes standards.

Interested in learning about ISO standards for fasteners? Check out this blog.

ISO 9001 is its quality management standard. It’s easily the most well-known and accepted quality management standard in the world. The standard itself is a 30 or so-page book that contains requirements for a company’s quality management system (QMS), which is basically all the policies and procedures put in place by a company to ensure that its products and services meet customer requirements.

The requirements in the ISO 9001 standard cover everything from product planning and development, to customer satisfaction, to everything in between. It’s meant to provide structure to create a holistic QMS that covers every aspect of quality.

*Note: the “2015” in ISO 9001:2015 refers to the year that particular revision was released. In this case, 2015 is the most recent revision, replacing the previous version released in 2008. IATF 19649:2016 and ISO 17025:2017 also follow this formula.

How Do You Get an ISO 9001:2015 Certification?

By becoming ISO 9001 certified, a company is dedicating itself to follow all the requirements set forth in the ISO 9001 standard. Here’s what that process looks like:

- The company structures its QMS, following ISO 9001 guidelines.

- The company submits to an audit by an accredited third party.

- The third party auditor performs an on-site audit to verify that the company is following all requirements of the ISO 9001 standard. They note all instances where the company’s QMS doesn’t adhere to the standard, and propose corrective actions for non-conformance.

- Any necessary corrective actions are completed by the company to ensure compliance.

- The third party auditor issues a certificate of compliance.

Hooray! The company can then claim ISO 9001 certification.

IATF 16949:2016 — An Overview

Next, IATF 16949. IATF, The International Automotive Task Force, is an organization of automotive manufacturers and their trade associations. Its purpose is to provide a consistency of QMS requirements for automotive suppliers that can be applied worldwide. Basically, the leading auto companies in the United States and Europe put together a task force that created a quality management standard of their own.

How Do You Get an IATF 16949:2016 Certification?

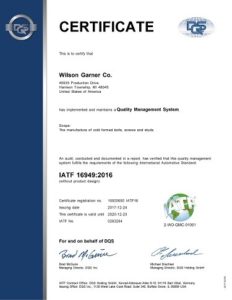

Any company that supplies parts that are mechanically or electronically attached to a vehicle is eligible to become IATF 16949 certified. An IATF 16949 certification is intended to exist on top of an ISO 9001 certification. Essentially, IATF 16949 is simply a list of extra requirements that automotive suppliers must adhere to over and above the requirements of ISO 9001.

IATF 16949 also required third party certification — and, since the IATF 16949 and ISO 9001 certifications are intertwined, most certification bodies will certify both at the same time.

And What About ISO 17025:2017?

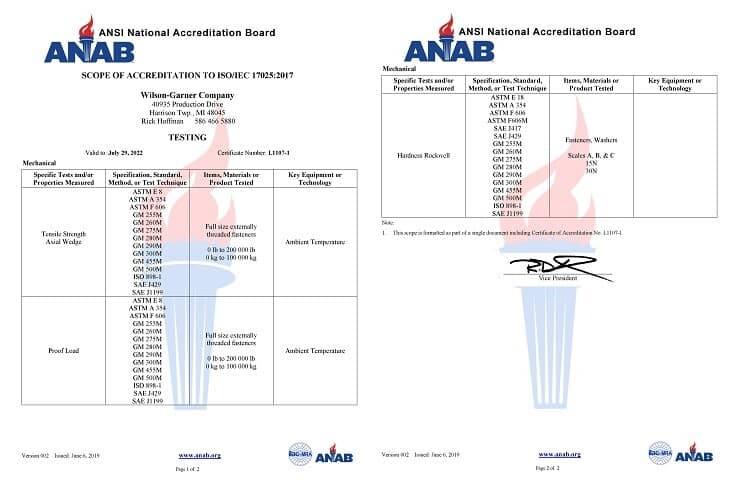

ISO 17025 is a bit of a different animal from the previous two standards discussed. Whereas IATF 16949 and ISO 9001 are quality management standards, ISO 17025 is a testing and calibration standard. It’s designed for laboratories that perform testing, sampling, or calibration. Labs can be either internal (testing only their own products) or external (testing outside clients’ parts).

Labs receive ISO 17025 certification for only the tests, sampling, and/or calibration they perform. The accredited tests, sampling, and calibration are listed in the Scope of Accreditation, which is usually attached to the ISO 17025 certificate.

Since it’s common for an automotive manufacturer to have their own internal lab, it’s possible and pretty common for the same company to have all three of the certifications we’ve mentioned: IATF 16949, ISO 9001, and ISO 17025.

What Are the Benefits of An IATF Certification or An ISO Certification?

IATF certifications and ISO certifications require considerable effort and commitment on the part of the manufacturer. So what’s the benefit, and why does anyone care about them? The answer is twofold.

First, simply the process of becoming certified to a quality or lab standard adds value to the organization. Having a template to build your QMS or lab upon is helpful, and the process of conforming to the standard most likely requires the company to improve upon current methods. In other words, if you’re going to put in the work to conform to an international standard, you might as well do it right and use it as an opportunity to improve.

Second, both potential and current customers see IATF certifications and ISO certifications as a shorthand assurance of quality. In fact, many customers will require you to have one of these certifications to do business with you. For example, most automotive original equipment manufacturers (OEMs) require IATF certification for their suppliers, and the Department of Defense requires ISO 9001 certification.

Learn About Wilson-Garner’s IATF and ISO Certifications & Discover Our Commitment to Quality

At Wilson-Garner, we hold all of the certifications mentioned in this post: IATF 16949, ISO 9001, and ISO 17025. You can find them on our About Us page.

If you’d like to learn more about our commitment to quality and how we can deliver the specialty fasteners you need, feel free to reach out online. We’re happy to walk you through our processes and provide you with effective solutions for your application.