Torque-tension testing is an aid to fastener and process engineers in developing installation torque specifications for industrial assembly operations. Fastener manufacturers also use these tests in product development. Torque-tension tests are used for free-spinning as well as locking products. This post will discuss basic tests for free-spinning applications.

Basics of the Bolted Joint

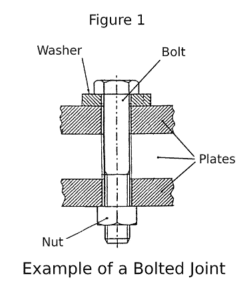

Before we can talk about torque-tension testing, we should take a second and define torque, tension, and the basics of the bolted joint. To put it simply, a bolted joint is two or more things held together with a bolt or screw. For the purposes of our discussion, we’re going to be specifically referring to a bolted joint as an assembly consisting of three metal plates with existing holes being joined together by a bolt, nut, and washer. See Figure 1 above. The holes are not tapped and therefore are not interacting with the threads. Also, in this example, we’ll be tightening the nut, not the bolt.

Before we can talk about torque-tension testing, we should take a second and define torque, tension, and the basics of the bolted joint. To put it simply, a bolted joint is two or more things held together with a bolt or screw. For the purposes of our discussion, we’re going to be specifically referring to a bolted joint as an assembly consisting of three metal plates with existing holes being joined together by a bolt, nut, and washer. See Figure 1 above. The holes are not tapped and therefore are not interacting with the threads. Also, in this example, we’ll be tightening the nut, not the bolt.

In order to tighten the nut, you turn it. The force required to rotate the nut is referred to as torque. As the nut is tightened, everything in the joint squeezes together as the nut moves up the threads. The force of this squeeze is referred to as tension (can also be referred to as clamp load.) As you tighten further and further, the bolt itself will begin to stretch. When the steel in the bolt is stretched, it tries to spring back to its original shape. So as the bolt stretches, it adds even more tension to the load as it tries to regain its original shape. If you were to keep tightening, the bolt would eventually become deformed permanently. The force at which a bolt becomes permanently deformed is called a bolt’s yield strength.

Torque-Tension Testing Basics

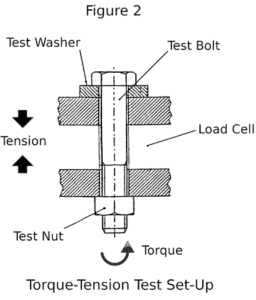

A torque-tension test is the measurement of the input torque required for a bolted joint to achieve a specified tension. In other words, how tight do I need to tighten my bolt in order for the joint to reach a certain tension? A typical test set-up is shown in Figure 2. It consists of a test bolt, test washer, and test nut loosely fitted in a test fixture. The test fixture contains a load cell that can measure the amount of tension in the joint.

A torque-tension test is the measurement of the input torque required for a bolted joint to achieve a specified tension. In other words, how tight do I need to tighten my bolt in order for the joint to reach a certain tension? A typical test set-up is shown in Figure 2. It consists of a test bolt, test washer, and test nut loosely fitted in a test fixture. The test fixture contains a load cell that can measure the amount of tension in the joint.

The nut is slowly tightened until a preset amount of tension is reached. As the joint is tightened, this action stretches the bolt, creating a clamp load on the joint (in this case the test fixture). The amount of torque needed to rotate the nut to the desired tension is measured. These tests are always run below the material’s yield strength, so no permanent deformation of the bolt occurs.

Friction

The most important factor affecting the relationship between torque and tension is friction. This makes sense: a nut with a smooth surface and lubrication will turn easier than one with a rough surface and no lubrication. There are several factors that can affect the amount of friction in a bolted joint. These include:

- Fastener material and grade – The type of material used and how hard it is will impact friction.

- Class of fit for mating threads – Thread systems with a tighter fit will have more friction than systems with a looser fit.

- Bearing surface properties and area – The amount of surface area and the roughness of the bearing surface will affect friction.

- Coatings – Different fastener coatings will have a large impact on friction.

- Lubricants – Different lubricants will also have a large impact on friction.

Coatings

Coating (sometimes referred to as finish or plating) on steel fasteners provides a number of desirable properties, including corrosion resistance. Different coatings also change the friction (lubricity) from that of a plain part. The coefficient of friction is a number that is calculated for each different coating. It can be calculated from torque-tension test results and part geometry. Coated test bolts are set up as in Figure 2. Torque measurements are made at a specified clamp load value, generally around 75% of the yield strength. This procedure is repeated a specified number of times, and the coefficient of friction is calculated from the results. The ability to determine a coefficient of friction for each coating is quite useful. This helps coating manufacturers develop and maintain products with consistent friction properties. End-user manufacturing companies also use the coefficient of friction to help determine installation torque values.

Where We Come In

Wilson-Garner Company does not actually perform any torque-tension testing. However, we have been supplying test bolts, nuts, and washers for over 35 years. We manufacture all of our test bolts, and we also stock test washers and test nuts. Many large OEMs have their own specifications for torque-tension tests that must be performed by suppliers. We stock parts for General Motors, Ford, Chrysler, and John Deere tests, as well as parts for tests based on ISO 16047. If there’s anything we might be able to help you with, by all means, let us know.

Wilson-Garner Company does not actually perform any torque-tension testing. However, we have been supplying test bolts, nuts, and washers for over 35 years. We manufacture all of our test bolts, and we also stock test washers and test nuts. Many large OEMs have their own specifications for torque-tension tests that must be performed by suppliers. We stock parts for General Motors, Ford, Chrysler, and John Deere tests, as well as parts for tests based on ISO 16047. If there’s anything we might be able to help you with, by all means, let us know.

This article was meant as an introduction to the subject, so if you’d like more information, we recommend taking a look at the ISO 16047 standard or individual OEM standards.

RELATED: Need a specialty bolt, screw, or stud? Wilson-Garner can help.