We’ve talked about how to use head markings to determine the different grades and manufacturers of inch-series bolts, but metric bolt and screw head markings are a whole different beast.

They’re not a beast we can’t tackle though. Let’s walk through how to decipher metric bolt and screw grades, plus their head markings, using one ISO standard and its following property classes as examples:

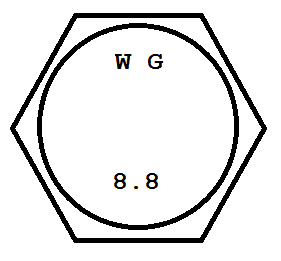

ISO 898-1 Property Class 8.8 Metric Bolt and Screw Head Marking

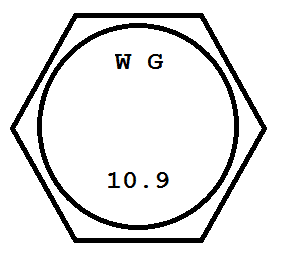

ISO 898-1 Property Class 10.9 Metric Bolt and Screw Head Marking

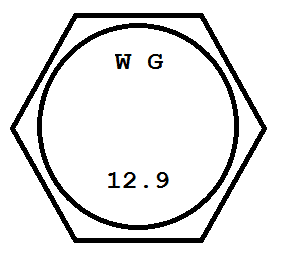

ISO 898-1 Property Class 12.9 Metric Bolt and Screw Head Marking

What Are Metric Fasteners?

Before we discuss the major metric spec we use at Wilson-Garner, ISO 898-1, let’s first explain metric fasteners in general. It’s important to be aware that metric fasteners are a part of a completely different system than inch-series fasteners. Metric fasteners have different units of measurement, different threads, and different specs.

Therefore, you can’t necessarily “convert” parts back and forth from metric to inch series, and vice versa. There are rough equivalents and points of overlap — for example, an M6 and a ¼” bolt are roughly the same diameters, and an M10X1.50 nut can be threaded onto a ⅜-16 bolt — but the systems are separate from one another.

Metric Terminology: Grade vs. Property Class

What’s a property class? Simply put, it’s the metric equivalent of a grade in inch-series terminology. One nice thing about ISO 898-1 is that the property class number designations have a concrete meaning. In SAE J429 grades like Grade 2 and Grade 8, the “2” and “8” don’t actually refer to anything — but with ISO 898-1 property classes, the number designations refer to real numbers.

That said, a property class designation consists of two numbers separated by a dot. Here’s what those numbers mean:

- The first number is 1/100th of the part’s nominal tensile strength in megapascals (MPa).

- The second number is 1/10th of the percentage of the part’s nominal yield strength compared to the part’s nominal tensile strength.

So, in English, a Property Class 8.8 bolt is a bolt with a nominal tensile strength of 800 MPa and a nominal yield strength that is 80% of that nominal tensile strength, so 640 MPa.

*Note: You probably noticed the use of the word “nominal” quite a bit in the last couple of sentences. That’s because the strengths indicated in the numbering system are meant to be ballpark figures and not necessarily the exact required strengths.

Alright, let’s jump into the spec.

ISO 898-1 Metric Bolt and Screw Head Markings

ISO 898-1 is the only spec we’re going to talk about here because it’s by far the most commonly used metric spec for fasteners. This standard covers bolts, screws, and studs made from carbon steel and alloy steel, and it lays out the requirements for ten different property classes.

Interested in learning about ISO standards for fasteners? Check out this blog.

Of ISO 898-1’s ten property classes, let’s focus on just three of them: Property Classes 8.8, 10.9, and 12.9. We’ll discuss what their metric head markings look like, and what some of their tensile strength requirements are.

ISO 898-1 Property Class 8.8 Metric Bolt and Screw Head Marking

Let’s first look at a Property Class 8.8 head marking:

One thing that’s nice about the ISO 898-1 property class designations is that the approximate tensile strength is right there on the bolt head marking. Property Class 8.8 bolts and screws have a minimum tensile strength of 800 MPa for bolts and screws 16mm in diameter and under, and 830 MPa for bolts and screws with a diameter over 16mm.

To give you an idea of how this compares to the strength of inch-series fasteners, 6.9 MPa are about equal to 1 kpi. 800 MPa are about 155 ksi. So a Property Class 8.8 bolt or screw is a medium-strength fastener that’s roughly the same strength as an SAE J429 Grade 5 fastener.

ISO 898-1 Property Class 10.9 Metric Bolt and Screw Head Marking

The Property Class 10.9 head marking is shown here:

Property Class 10.9 bolts and screws have a minimum tensile strength of 1040 MPa for all sizes. As you can see, they’re slightly stronger than the nominal value in the property class designation. Property Class 10.9 bolts are considered high-strength parts. They’re in the neighborhood of SAE J429 Grade 8 parts.

ISO 898-1 Property Class 12.9 Metric Bolt and Screw Head Marking

Finally, here’s the Property Class 12.9 head marking:

And there’s nothing surprising about it! Property Class 12.9 bolts and screws have a minimum tensile strength of 1220 MPa for all sizes. 1220 MPa are roughly equivalent to 175 ksi. These parts are very high in strength. In fact, they’re the strongest of all the fasteners we’ve covered in our inch-series and metric bolt head marking blogs.

Learn More About Metric Bolt and Screw Grades

with Wilson-Garner

Interested in learning a bit more about bolt and screw head markings? While this is currently our only blog on metric grades and head markings, we do have a few others you should check out on inch-series parts:

And if you have any questions that these blogs can’t answer for you, feel free to reach out to us. With plenty of experience in the fastener industry, we’ll likely have an answer for you. Give us a call at (800) 656-2658 or contact us online.

Comments are closed.