Generally speaking, there are two main methods of producing external threads on a fastener: rolling and cutting.

Wondering which one may be best for your application? Let’s take a look at rolled threads vs. cut threads, examine the differences between them, and identify what advantages and disadvantages each brings to the table.

What Are Rolled Threads?

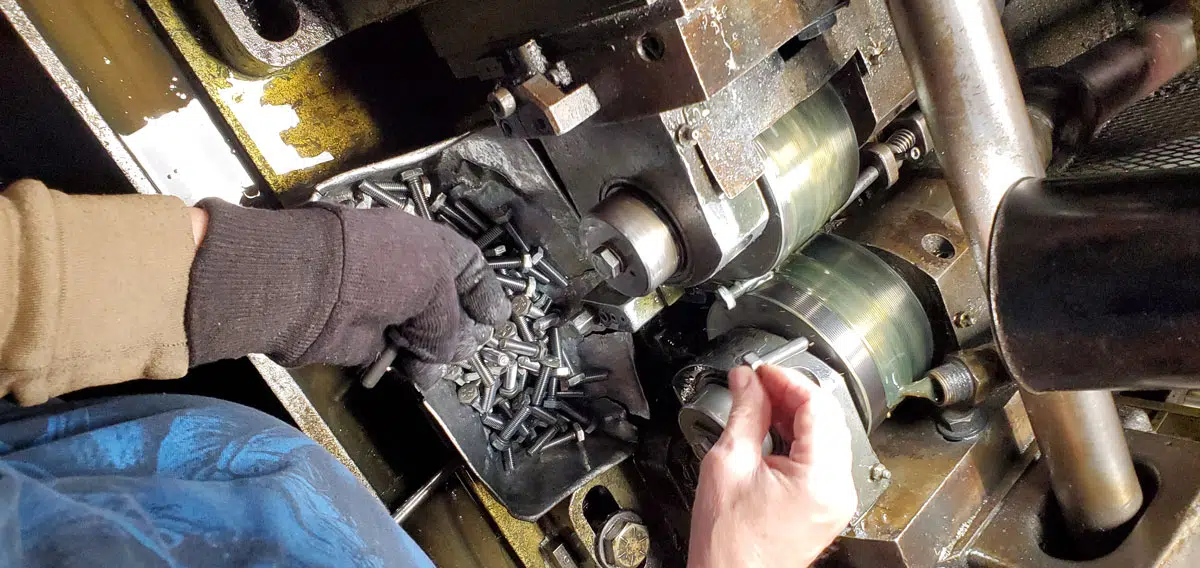

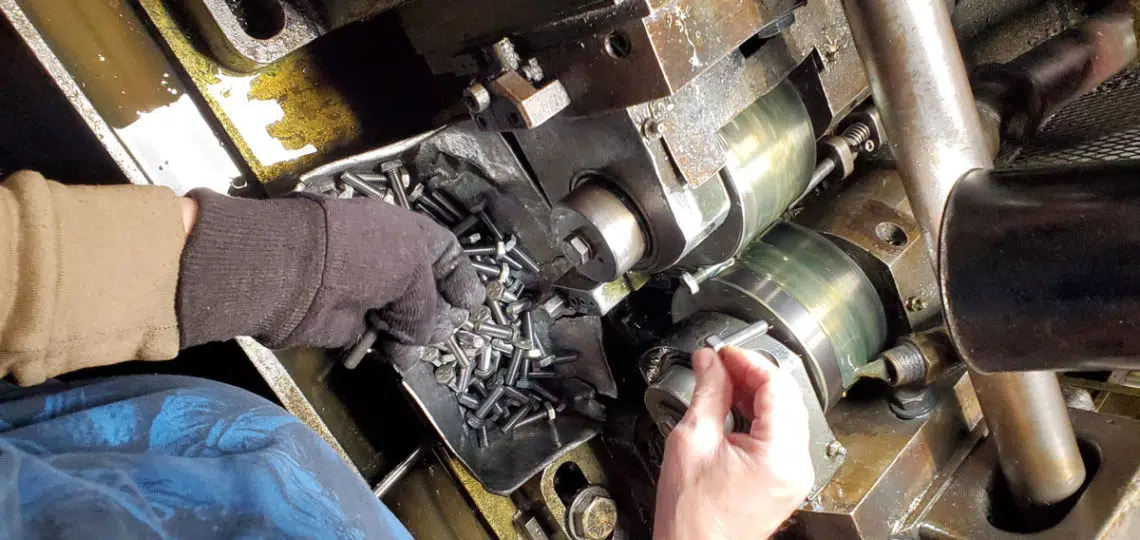

Rolled threads are formed by pressure. Basically, the fastener is rolled through a set of threading dies that displace the material to form threads, without removing any of the material or changing its grain structure. Roll threading is a cold forming process, meaning there’s no heat added to transform the part.

Advantages of Rolled Threads

Rolled threads come with many advantages in terms of performance and efficiency. Here are a few of them:

- Enhanced strength – When a material is shaped without being cut or heated, it maintains the grain structure of the steel, with grains flowing along the contours of the part. This is a process called “work hardening,” which enhances the strength of the part.

- Consistent precision – Thread rolling ensures the most consistent, quality results possible — and relatively quickly, too!

- Reduced waste and energy consumption – Since you don’t need to cut any material and you don’t need energy to heat any material, thread rolling offers facilities significant time and cost savings.

Disadvantages of Rolled Threads

Although rolled threads are great for many applications, the thread rolling process does have some drawbacks, including:

- Size, shape, and material limitations – As much as thread rolling capabilities have improved over the years, parts with large sizes, unique shapes, and/or unconventional materials aren’t able to be rolled.

- Rolled from the pitch diameter – Since they’re rolled from the pitch diameter (a diameter that is halfway between the major and minor diameters of the part), you’ll likely need to form the major diameter for the part’s body, and then form the pitch diameter for its threaded component. This extra step isn’t usually a huge deal, but it is something to take into account during the manufacturing process.

RELATED: Need a specialty bolt, screw, or stud? Wilson-Garner can help.

What Are Cut Threads?

Cut threads are formed through a method of cutting away, or removing, material from a round bar. This is usually done using a threading die or a single-point cutting tool.

Advantages of Cut Threads

There are some facilities that prefer thread cutting, mainly because of the following two advantages:

- Versatile capabilities – Thread cutting is compatible with parts of all specifications, even large diameter sizes. For the large-sized, uniquely shaped parts that thread rolling can’t typically handle, thread cutting is a suitable alternative.

- Suitable for parts with cavities – In addition to versatility in size and shape, thread cutting is also a suitable choice for parts with cavities, such as pipes.

Disadvantages of Cut Threads

However, as thread rolling processes have advanced over the years, many manufacturers have begun to see more and more disadvantages of thread cutting, including:

- Slower production rates – Thread cutting typically takes a bit longer than thread rolling, which decreases production speed and increases labor costs.

- Reduced strength – Unlike thread rolling, thread cutting doesn’t allow for any work hardening to occur. Instead, removing material causes changes in the part’s grain structure — ultimately resulting in a loss of strength.

- Threatened durability – Cutting threads can easily result in tiny, unwanted tears in the material, which can expand over time and threaten the part’s longevity.

- High amount of waste – Removing material from parts leads to a lot of waste that needs to be managed. The scraps are also usually pretty nasty and sharp to deal with.

Rolled Threads vs. Cut Threads: Which is Best for My Application?

Based on all that information, you can probably conclude that rolled threads are often the best choice. They’re consistently more durable, accurate, and resource-efficient than their cut counterparts.

However, there are still some applications where cut threads are beneficial. If you’re working with large-diameter parts or parts that have cavities, their versatility makes them a more suitable choice.

Find Durable, Thread-Rolled Fasteners at Wilson-Garner

At Wilson-Garner, we use cold forming and thread rolling to produce durable fasteners. Ideal for a range of applications, we can deliver the quality solution you need based on your unique specifications. Call us or contact us online to get started.