Advancements in additive manufacturing technology are reshaping industries. With all the buzz about 3D printing, it’s natural to ask if the technology could eventually replace tried-and-true fastener manufacturing methods.

My short answer is no…not yet at least. But depending on your needs, both approaches have their place.

TL;DR: 3D-Printed vs. Cold-Formed Fasteners

Can You Print 3D Fasteners?

Yes, you can 3D print fasteners. Using metal powder bed fusion (PBF), binder jetting, or high-performance polymers, it’s possible to create bolts, studs, and screws.

You can 3D print just about anything these days. The real question is whether you should.

If you only need a few pieces for prototyping and aren’t worried about strength, 3D printing might make sense. But if you need hundreds (or more) of high-strength fasteners, I advise sticking to traditional manufacturing methods. I’ll give more details as to why below.

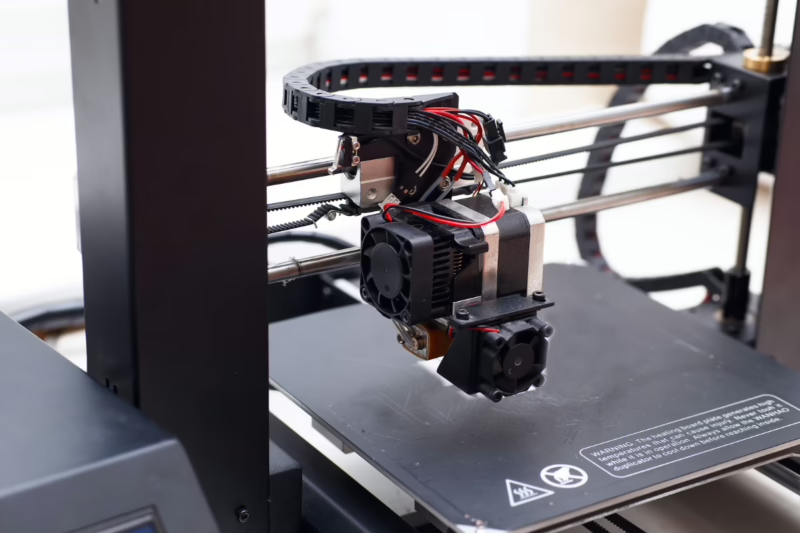

How 3D-Printed Fasteners Are Made

3D-printed fasteners are designed using computer-aided design and then built layer by layer from powders, resins, or polymers. Depending on the method, lasers, binders, or heat fuse the material together. The most common materials used to 3D print fasteners are stainless steel powders, titanium alloys, and high-performance polymers and composites.

This technology allows for a high level of design flexibility and customization. You can produce shapes and geometries without needing new tooling for traditional methods like hot forging and cold forming. But there are trade-offs.

Pros and Cons of 3D-Printed Fasteners

When 3D-Printed Fasteners Make Sense

These are the use cases where I can see 3D-printed fasteners being successful:

- You’re testing a prototype and only need a few pieces

- You’re working on a non-structural application where strength isn’t important

So maybe they’re a good complement to traditionally made fasteners, but not a replacement.

The Challenges Holding Back 3D-Printed Fasteners

The drawbacks of 3D-printed fasteners are significant for most industrial applications. Because they’re built layer by layer, internal porosity and weaker grain structure make them less reliable under high loads compared to cold-formed fasteners. Production speed is also a major hurdle, as additive manufacturing can only produce one part at a time, which drives up per-part costs and limits scalability. Even when the part is complete, many prints require post-processing such as machining or polishing to achieve the surface finish needed for proper fit and performance.

Finally, industries like aerospace, automotive, and energy often impose strict safety and certification requirements that 3D-printed fasteners can’t consistently meet yet, keeping their adoption limited to niche and experimental projects.

How Cold-Formed Fasteners Are Made

Cold forming, also known as cold heading, is the process of forming a fastener without heating up the material. This is typically done by pressing the material into dies with high-pressure machinery. Instead of cutting material away, the die compresses and displaces it, which strengthens the material in the process.

That’s why cold-formed fasteners are so reliable. If you work in the automotive, aerospace, energy, or any industrial field, chances are your fasteners are cold formed.

You can read more about the cold forming process in this blog.

Pros and Cons of Cold-Formed Fasteners

For most industries and applications, cold-formed fasteners remain the clear choice. They bring the strength, consistency, and cost-effectiveness needed for large-scale manufacturing operations.

Get the Highest Quality Fasteners for Your Project

Manufacturing will continue to evolve as new technologies emerge, but until 3D printing technology advances even further, I believe cold-formed fasteners are the best solution.

At Wilson-Garner, my team specializes in custom, cold-formed fasteners manufactured to the highest quality. We manufacture every order at our facility based in Harrison Township, Michigan, and are able to support limited-run quantities. So if you need a small batch of fasteners that will meet your strength and performance requirements, we’ve got you covered.

You can request a quote online or send us a message to learn more.