We’ve talked a lot about screws, and we’ve talked a lot about bolts. But what about studs?

Here’s an overview of the key information to know about stud fasteners — including what they’re used for and what different types are available.

What Are Stud Fasteners?

Studs are externally threaded fasteners that typically look like and operate as threaded bars. They’re different from screws and bolts in the fact that they don’t usually have a head that requires tightening — just continuous threading that can be paired with nuts.

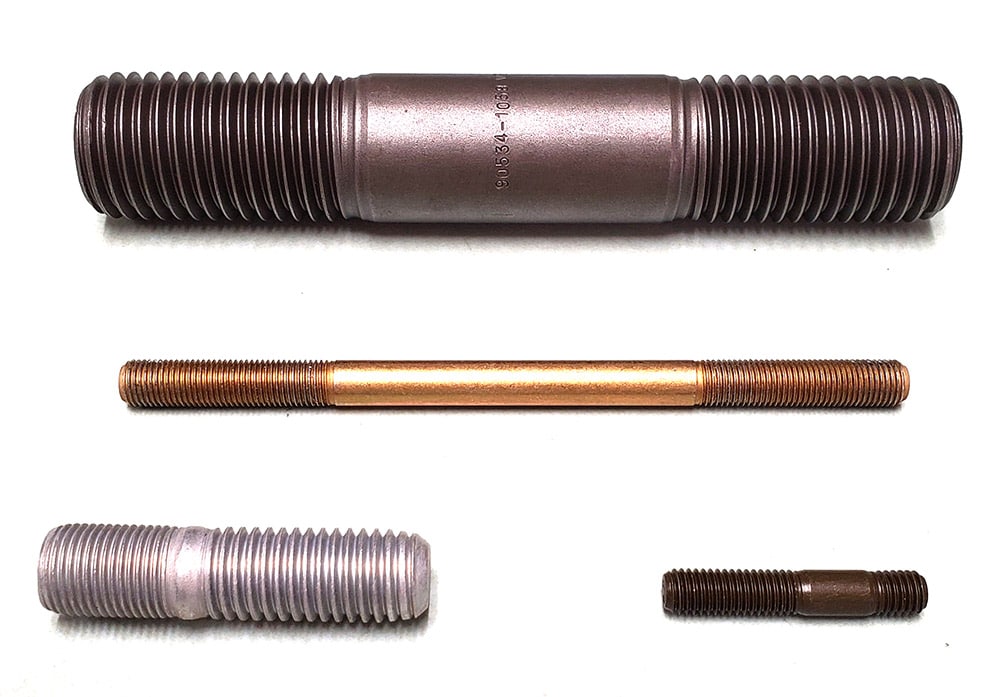

However, studs are versatile fasteners that come in various shapes, styles, and sizes. So while the continuous threaded studs mentioned above are probably the most well-known, there are a bunch of other types of studs you may come across, such as:

- Studs that have no head, threads at only one end, and the rest is body

- Studs that have threads at both ends, and an unthreaded body in the middle

- Studs that have different threads at both ends, and an unthreaded body in the middle

- Studs that have different diameters at both ends, and an unthreaded body in the middle

- Studs that have a hex or collar in the middle

- Studs with a head at one end to be permanently attached to a tapped component via welding, swaging, or bonding

As you can see, there are lots of options here, and that’s only really the start of them. But all of that variety and versatility is what makes studs so useful.

What Applications Are Stud Fasteners Used For?

Studs are most commonly used for joining two components with internally threaded holes, like nuts, together. But that’s a pretty broad description, so we’ll also list some of the most common applications they’re used for.

Stud fasteners are often used to:

- Wheel hub assemblies

- Fasten flanges and gaskets

- Prevent fluids from leaking through holes in machines

- Assemble heavy-duty materials like turbines and tanks

But, of course, these applications could all change depending on which type of stud you’re working with. There are almost endless possibilities here.

RELATED: Need a specialty bolt, screw, or stud? Wilson-Garner can help.

What Are Some Different Types of Stud Fasteners?

Now, for some specific types of studs. While some of these were described above, here are more details on their actual names and what features they include.

- Fully threaded stud – This is the most common, recognizable type of stud. It’s essentially just a length of threaded bar, which is frequently paired with nuts at each end.

- Double-end stud – This type of stud has threading at each end and an unthreaded body in the middle. In some cases, the ends have similar threads and diameters; in other cases, they’re different. Either way, both ends are usually intended to accept nuts.

- Hex stud – This type of stud is threaded at both ends, but has a hex or collar in the middle.

- Tap end stud – This type of stud has a short length of thread at one end that’s intended to screw into a tapped hole. Then, after an unthreaded shank in the middle, the other end has a long length of thread that is usually paired with a nut.

- Flange stud – This type of stud has a continuous threaded body and chamfered ends. It’s intended to accept two nuts at opposite ends, which are tightened to secure pipe flanges.

- Wheel stud – This type of stud usually has threading at one end, a body, a knurled section, and a head. The knurl is designed to be pressed into and grip the wheel hub, securing the vehicle wheel in place.

Wilson-Garner Can Manufacture the Specialty Stud Fasteners You Need

Need a speciality stud, bolt, or screw for your application? Wilson-Garner can help. We’re experts in manufacturing American-made, blueprint-specific, limited-run fasteners, and we’d be happy to deliver a solution that works for you. To get started working with us, contact us online today.