Fastener threads are quite amazing when you stop to think about them.

Yeah, we know, nobody ever stops to think about fastener threads.

But consider this: a properly manufactured bolt subject to extreme tensile stress will break across its diameter before the threads will shear. In other words, the threads are stronger than the weakest part of the bolt itself. Also, in that same scenario, if the majority of the force was concentrated on the bottom two threads and not spread out evenly, the threads still won’t shear before the bolt breaks.

Fastener threads are cool. Here’s some basic thread terminology and spec information if you’d like to know more about how they work.

Internal vs. External Fastener Threads

There are two main types of fastener threads: internal and external. They differ primarily in their location and application.

- Internal threads are located inside a tapped hole or a nut. They receive the external thread of a bolt, screw, or stud.

- External threads are located on the outside of a bolt, screw, or stud. They fit into the internal threads of a tapped hole or nut.

At Wilson-Garner, we exclusively manufacture fasteners with external threads (bolts, screws, and studs), so that’s where our focus is in this article. If you’d like to learn more about internal fastener threads, we discuss them more here.

External Fastener Thread Terminology

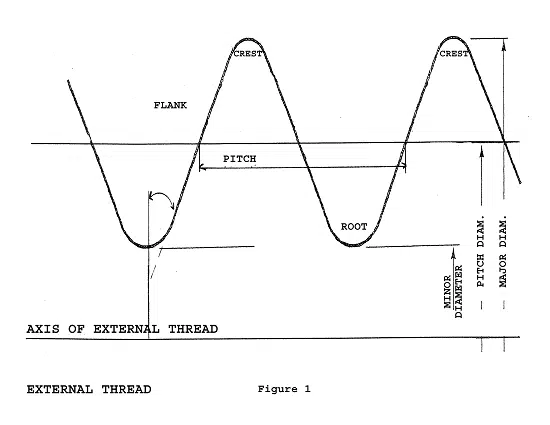

There’s a lot of terminology that gets thrown around when talking about fastener threads. We’ve simplified it with the labeled diagram below.

Thread Terms & Definitions

- Crest: The top of the thread

- Root: The bottom of the thread

- Flank: Connects the crest and the root

- Pitch: The distance measured parallel to the thread axis between corresponding points on adjacent threads. So, pick a spot on the thread and measure the distance to the same spot on the next thread.

- Major Diameter: The diameter of the fastener as measured at the crests of the threads

- Minor Diameter: The diameter of the fastener as measured at the roots of the threads

- Pitch Diameter: The diameter of a theoretical cylinder passing through the threads in such a manner that the distance between the crests and roots is equal.

Need a refresh on more fastener terminology? Head to this article.

How to Speak Thread – Inch Version

Now, let’s give those terms and definitions some context. In the interest of keeping this article a reasonable length, we’ll talk exclusively about Unified Inch threads. (If you want to know more about metric threads, don’t worry — we also have an article that covers those.)

We’ll start with an example that will demonstrate how we express inch threads.

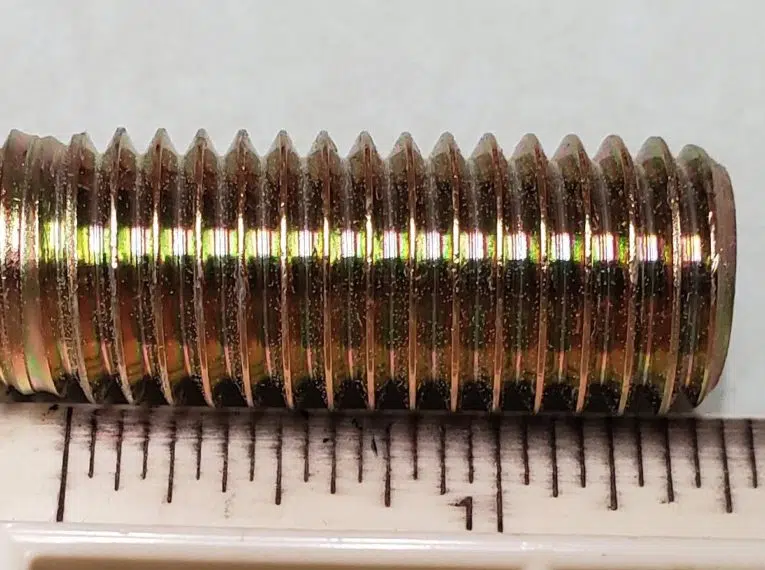

The photo above is of a double-end stud with ⅝-11 UNC 3A threads. Here’s the breakdown of what that means.

The “5/8”: Nominal Major Diameter

The ⅝ refers to the nominal major diameter of the threads. You’ll remember from above that major diameter is the diameter of the threads as measured at the crests. And then we just use “nominal” to mean “more or less;” the major diameter has a built-in tolerance anywhere between 0.6129–0.6250”, but we just call it “⅝” because that’s easier.

The “11”: Threads Per Inch

The 11 refers to the number of complete threads in one inch of threaded length, or threads per inch. Count them for yourself!

The “UNC”: Thread Class

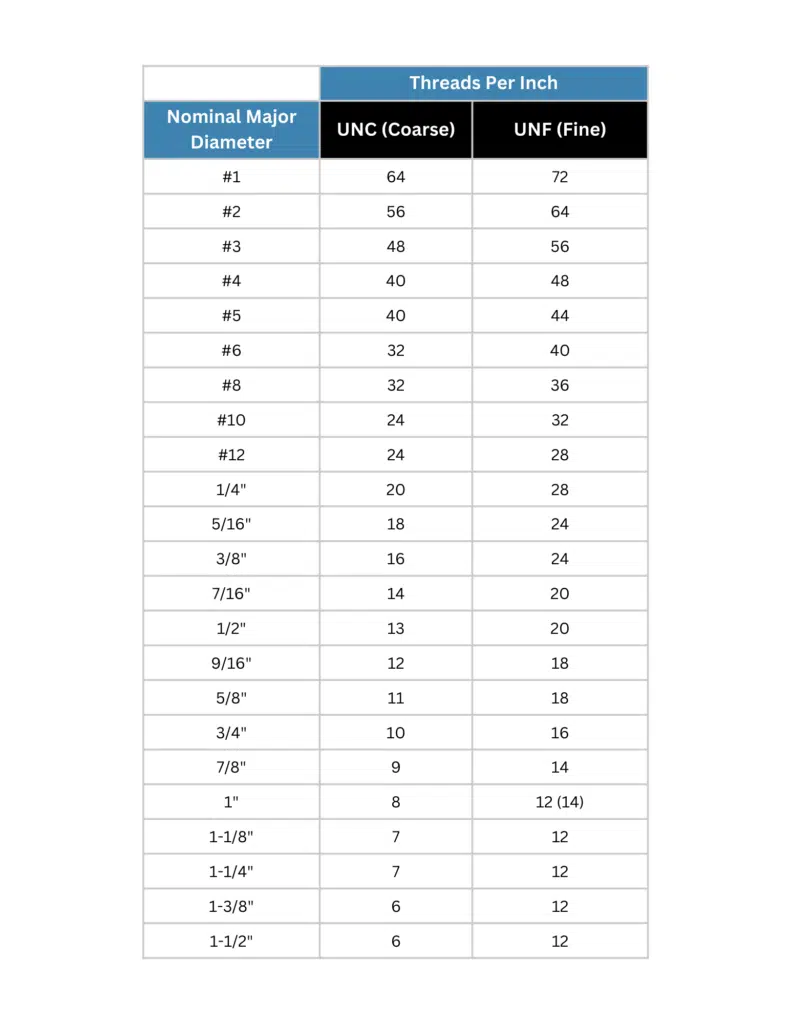

Unified Inch threads have two major classes: UNC (coarse) and UNF (fine). Coarse threads have fewer threads per inch than fine threads. If the above example were a UNF thread, it would be ⅝-18 instead of ⅝-11, meaning it would have a ⅝” nominal diameter and 18 threads per inch instead of 11. Every nominal inch size can have UNC and UNF versions like this. Here’s a pretty decent chart:

The 3A refers to a class of thread fit for external threads. Thread fit is a measure of the looseness or tightness between mating threads when an externally threaded fastener is assembled into an internally threaded nut or tapped hole. If you’d like to learn more about thread fit, check out Part 2 of our Threads Series.

Talk to Our Fastener Manufacturing Experts

Hopefully, this article has been a helpful introduction to external threads, but there’s always plenty more to learn. If you have questions that are still unanswered or you’re looking for a special externally threaded fastener, we’re here to help.