When it comes to screws, bolts, and other threaded fasteners, precision and accuracy are critical. Engineers and manufacturers rely on standardized measurements and classifications to ensure seamless assembly and optimal performance.

In Part 1 of our Threads Series, we provided some terminology and explained some of the nomenclatures of Unified Inch series threads. Now, we’ll look at three particular classes of fit within that series, as we discuss the difference between 1A, 2A, and 3A threads.

What Are 1A, 2A, and 3A Fastener Threads?

The terms “1A,” “2A,” and “3A” refer to classes of fit for external Unified Inch series threads on screws, bolts, and studs. Internal threads, such as those found in nuts or tapped holes, have thread fit classes termed “1B,” “2B,” and “3B.” The A/B mating parts are designed to fit together to allow free-running assembly with no interference.

The term “thread fit” is defined as the measure of the looseness or tightness between mating threads when an externally threaded fastener is assembled into an internally threaded hole or nut. As you’ll see below, 3A/3B is a tighter fit than 2A/2B, and 2A/2B is a tighter fit than 1A/1B.

1A vs. 2A vs. 3A Threads

TL;DR — The key distinction between 1A, 2A and 3A threads lies in their thread fit characteristics and tolerance levels.

| 1A Threads | 2A Threads | 3A Threads |

|

|

|

To understand the difference between these fastener threads, you must first understand thread fit, allowances, and tolerances. Basically, thread fits are developed using allowances and tolerances.

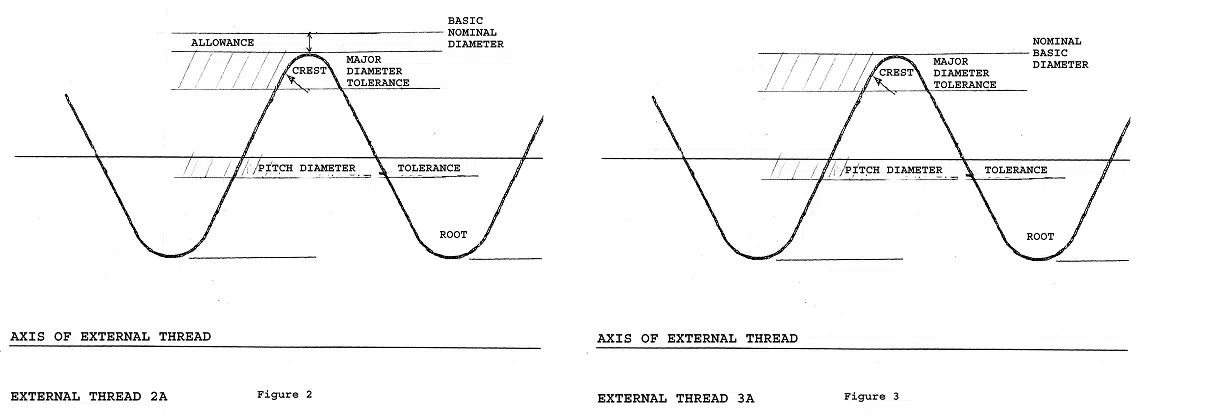

An allowance is an intentional clearance between mating threads. Allowances are applied to external threads. The major, pitch, and minor diameter maximums are less than the basic size by the amount of the allowance.

A tolerance is the difference between the maximum and minimum permitted limits for a given dimension. Tolerances are specified amounts by which dimensions are permitted to vary for manufacturing convenience.

And here’s the main difference between the three types of bolt, stud, or screw threads:

- Class 1A threads have standard allowance and lots of tolerance (loosest fit)

- Class 2A threads have standard allowance and tolerance (medium fit)

- Class 3A threads have no allowance and close tolerance (tight fit)

The two diagrams below should nicely illustrate allowance and tolerance.

Here’s an Example

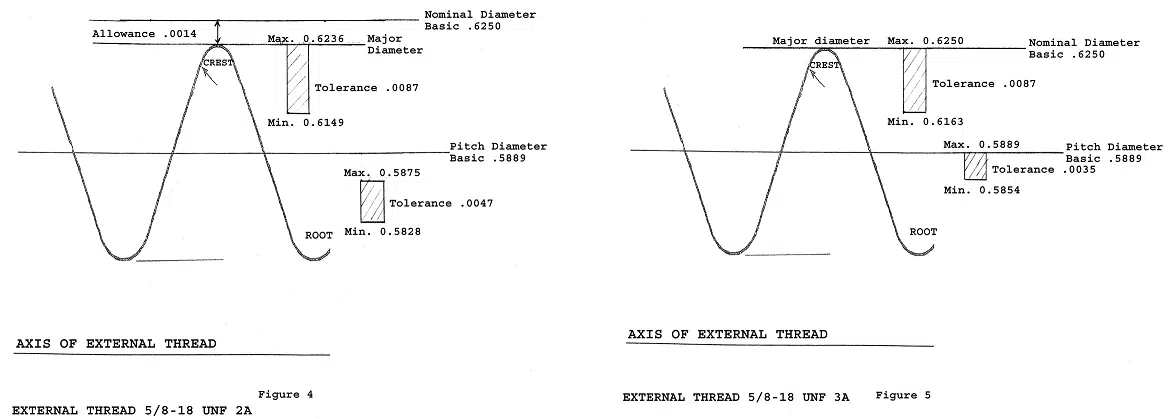

Let’s look at a specific example. This one compares 2A and 3A threads (we don’t manufacture parts with 1A threads at Wilson-Garner). The difference between class 2A and 3A external threads is shown below for 5/8-18 UNF parts.

Note that for class 2A, both the major and pitch diameter maximums are below their respective basic values by the 0.0014 inch allowance. The allowance is 30% of the class 2A tolerance.

For class 3A, the major and pitch diameter maximums are at the basic size. Also, the pitch diameter tolerance for class 3A is 0.0035 inches, which is smaller than the class 2A tolerance of 0.0047 inches.

A Side-by-Side Comparison

A Side-by-Side Comparison

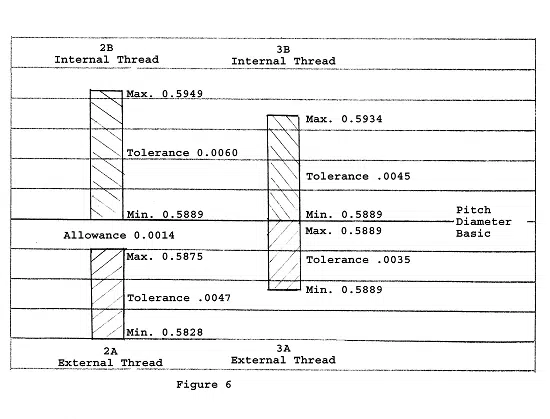

Now that we’ve examined an example of external threads, we are going to look at an entire mated thread system. Keeping the 5/8-18 example, let’s look at a side-by-side comparison of the complete clearance.

The complete clearance consists of the allowance (if any) for the external thread and tolerances for the external and internal mating threads. See Figure 6 below for a side-by-side comparison of 5/8-18 UNF 2A/2B and 3A/3B pitch diameter. The 3A/3B thread fit has no allowance and smaller tolerances than the class 2A/2B thread fit, resulting in a tighter fit.

Learn More About Bolt and Screw Threads

We’ve provided some basic facts about Unified Inch series threads here. For more information, we recommend referring to the ANSI/ASME B1.1 standard.

Our Threads Series continues in Part 3, where we provide a brief overview of metric series threads.

At Wilson-Garner, we produce small-quantity bolts, screws, and studs that are difficult to find everywhere else. View our capabilities, then contact us or request a quote to see how we can help you.

RELATED: Need a specialty bolt, screw, or stud? Wilson-Garner can help.

A Side-by-Side Comparison

A Side-by-Side Comparison

Comments are closed.