When most people think of a screw, the most common Phillips head is likely to come to mind. However, just like there are hundreds of fastener types available for use, there’s also a multitude of unique screw head types, each offering their own purpose and benefits.

Let’s explore how many unique screw head types there are, why there are so many of them, and what a few of them are specifically used for.

How Many Screw Head Types Are There?

As mentioned above, there are a lot of screw head types. The exact number is difficult to count, but it’s probably nearing the hundreds. And when you consider all the modifications made for specific applications, that number continues to rise.

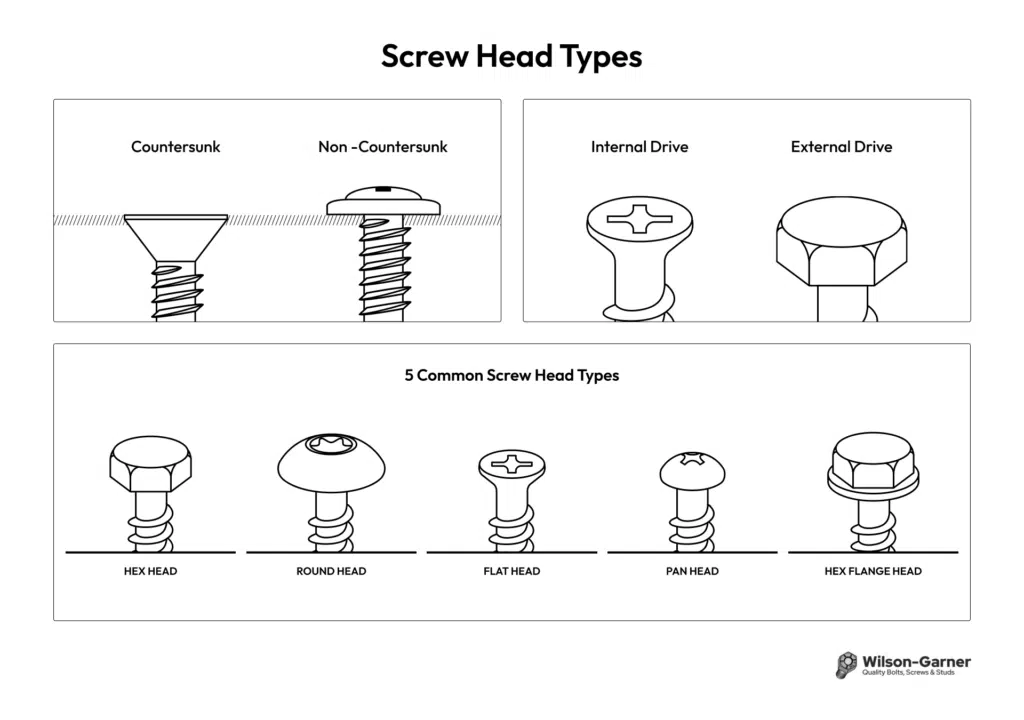

So how do you account for each of these head types, and how do you determine which is right for your application? There are a few ways, but the best is to narrow it down by categorizing them. While there are a few different methods of screw head categorization, the most common are countersunk vs. non-countersunk, and internal vs. external drive.

Countersunk vs. Non-Countersunk

Countersunk vs. Non-Countersunk

Countersunk and non-countersunk design refers to how much of the screw head is exposed after being applied. All screw heads can be categorized into one of these two categories.

- Countersunk screw heads rest evenly with the material surface after installation. Their design tapers toward the shank, allowing the head to essentially “sink” into the surface.

- Non-countersunk screw heads protrude from the material surface after installation, leaving the head fully exposed. Instead of tapering toward the shank, non-countersunk screws have a narrow shank that’s topped with an abrupt wide head. This category encompasses the largest number of screw head types.

Internal vs. External Drive

The drive style, or drive recess, refers to what kind of tool you use to install or remove the screw. Basically, this means that screws can be categorized by whether a tool needs to be inserted in or wrapped outside of the screw head for installation or removal.

- Internal drive screw heads require a tool, like a screwdriver, to be inserted within the head for installation and removal.

- External drive screw heads require a tool, like a wrench, to wrap around the head for installation and removal.

Why Are There So Many Unique Screw Head Types?

All of this begs the question: why are there so many different screw head types? And the answer isn’t just to drive you crazy or make you have a thousand different tools on hand at all times.

Instead, there are many different screw heads because each screw head style allows for different torque. Every screw head type was created to transfer torque (energy) more effectively from a particular drive mechanism, or tool — helping its threaded body twist into a hole easier and with more tightness. The variation in heads allows you to choose the one that will make your application stronger and more dependable.

RELATED: Need a specialty bolt, screw, or stud? Wilson-Garner can help.

5 Common Screw Head Types and Their Uses

Now, let’s take a look at some of the more common screw head types and their uses. This can help get a feel for which applications require which types of heads, and why.

- Hex head – Also common in bolts, hex heads provide superior torque due their external drive design. They’re used in many applications involving construction and machinery assembly.

- Round head – Round heads offer a more finished appearance than some other rounded screw alternatives. They’re used for applications where aesthetics and smooth appearances are necessary.

- Flat head – As their name suggests, flat heads are countersunk and allow for a flat and smooth surface post-installation. They’re used in applications like furniture and machinery assembly, where sleek design is important.

- Pan head – Pan head screws are non-countersunk screws that typically have a mushroom-shaped head with a flat bottom. They are versatile and typically used when the screw head is exposed. Often used in metalwork, woodwork, and machinery.

- Hex flange head – Hex flange heads also provide great torque and dependability, even in harsh conditions. They’re commonly used for construction, heavy machinery, and vehicle framing applications.

If your application requires a unique type of screw head, Wilson-Garner can help you figure out a solution. We specialize in non-standard, American-made, limited-run fasteners. From head to thread, we’re proud to manufacture parts that meet customer blueprint specifications. Contact us to learn more about what we can do for you.